During the last quarter of year 2020 we have commissioned the Tension Leveling Line for aluminium coils at the company IBERFOIL, a part of the Spanish group ALIBERICO and former Alcoa Sabiñanigo Plant in Northern Spain.

The company specializes in rolling and processing high quality aluminium products for a wide range of sectors like pharmaceutical, packaging, construction, automotive, fin stock, etc.

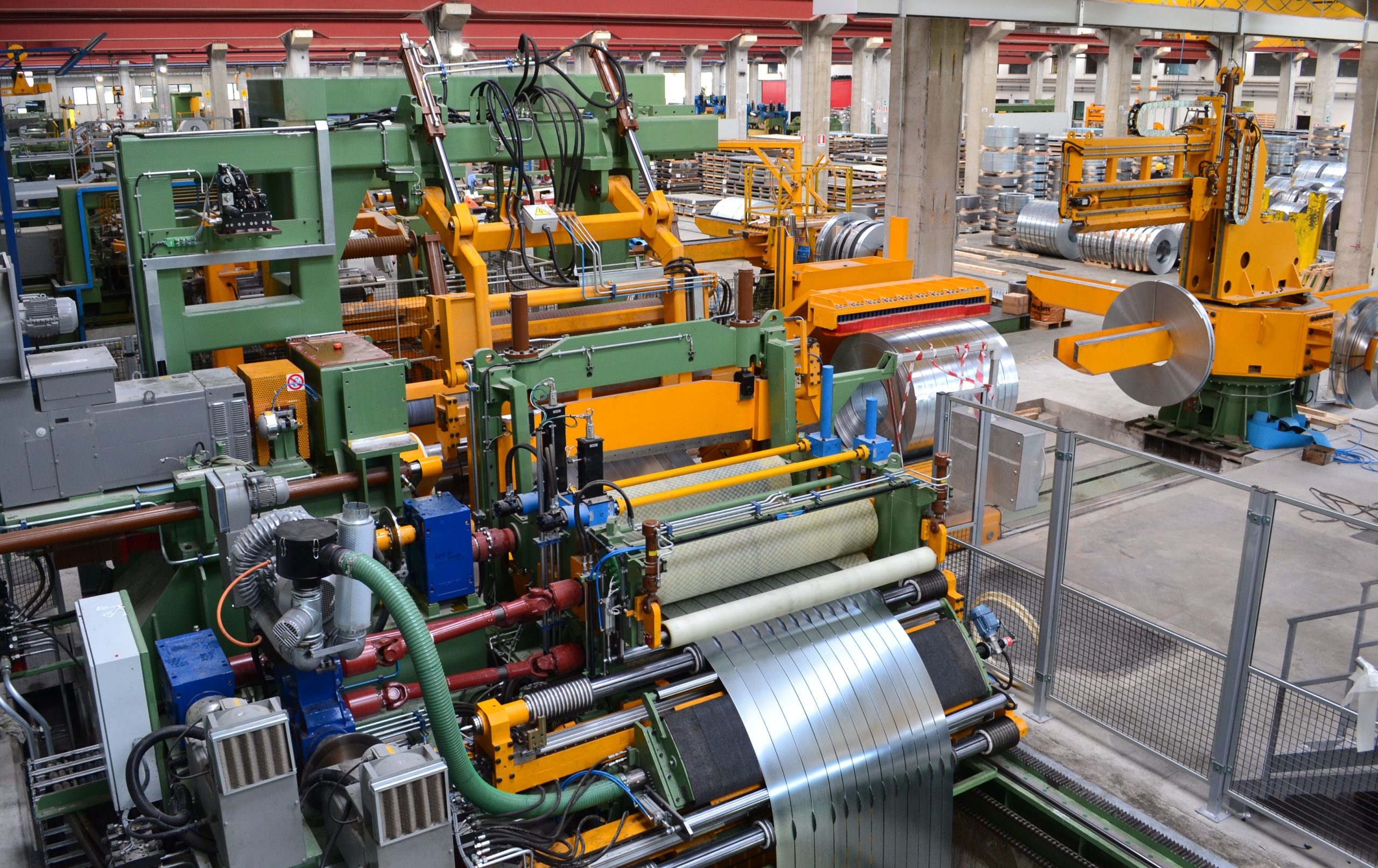

The Tension Leveling Line processes aluminium coils of 1.650 mm in width and a thickness range from 0.2 up to 1.6 mm.

The line features a heavy duty tension leveler that operates with a maximum strip tension generated by the bridles of 30 tons. A double elongation section is followed by a double decurving section with all the clusters of rolls mounted on extractable cassettes to the sides of the machine for easy and ergonomic cleaning and maintenance tasks.

The line has a void space for the future integration of an alkaline degreasing section that will be supplied in the second stage of the project.

The erection and commissioning works took place during the months of pandemic and thanks to the big involvement and compromise of the project teams from both Iberfoil and Salico, the line entered in production as per the original project time schedule without any delay caused by the pandemic.

From here we want to convey our thanks to IBERFOIL for having selected us for the supply of this very interesting finishing line and for the very positive and cooperative attitude maintained all along the project.