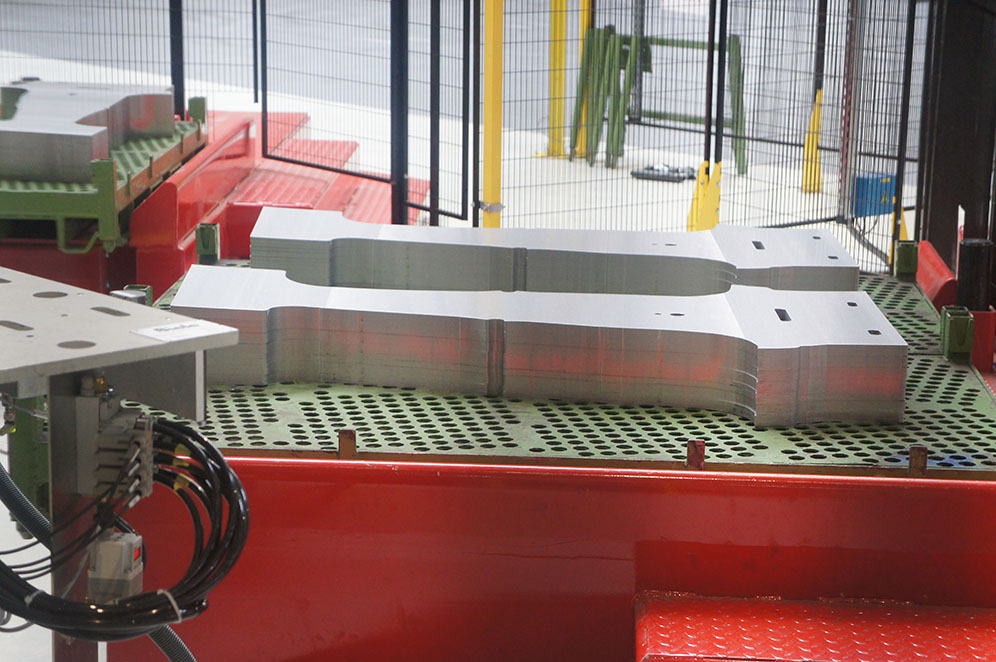

SALICO supplies blanking lines mainly focused to the automotive industry-oriented service centers. Typically strip thickness ranges from 0.4 to 4 mm, maximum width being 2,100 mm and speed up to 100 m/min.

SALICO will team up with the main constructors of blanking presses in the world with optimum results and with all issues related to integration and coordination fully under control.

SALICO equipment design is oriented to reach a high yield, high quality products, low breakdown rates, ease of maintenance and most of all a safe and ergonomic operation, leading to a fast return on the investment.

SALICO Advantages

Safe and ergonomic operation

Even with thickest and hardest of materials.

High quality leveling ensures internal stresses relief

Levelers can deliver high yielding rates of strip cross section (85%) in order to process in an optimum way a wider range of thickness than most of our competitors.

High Productivity

By minimizing line down time by automating rolls exchange operations, rolls continuous cleaning devices, as well as enabling the automatic set up of line main components without operator intervention, starting from production data coming from upper IT levels.

Teaming up possibilities

With any blanking press supplier.