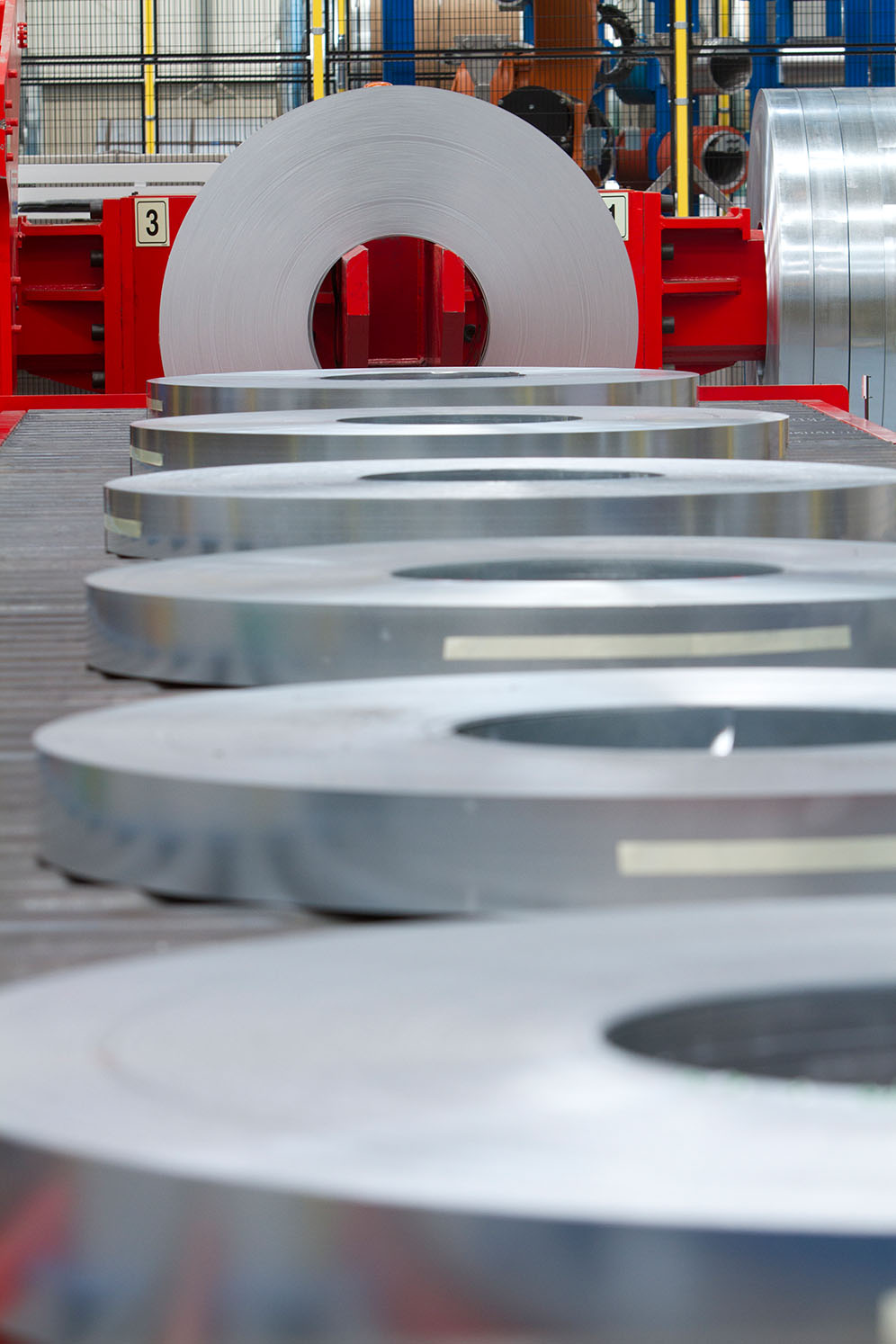

SALICO supplies packaging lines for complete coils, slit coils or packages of sheets either as final section within a new or existing slitting or cut to length line or as independent stand alone facilities.

Packaging lines are designed following specific customer requirements and taking into account the final shape, characteristics and variants of the final packages, desired level of automation, available floor space and materials Flow, which regularly results in tailor made solutions.

SALICO supplies all kinds of packaging lines, ranging from simple and manual ones to completely automated solutions, where individual equipment from third parties to perform specific tasks may be included, as the following example for a slit coils packaging line:

- · Slits down ending.

- · Individual slit weighing.

- · ID banding, with one or two strapping heads.

- · Slit wrapping with either paper or plastic film.

- · Application of sticking label on the individual slit.

- · Spacers application.

- · Pallets loading and feeding.

- · Pick up and palletizing of sits eye to sky.

- · Slits stack film protection.

- · Cover feeding.

- · Final stack strapping.

- · Final stack weighing.

- · Stack labelling.

In the case of full coils, these would be the typical operations:

- · Edge protection application, both in ID and OD.

- · Film and paper application through coil ID.

- · Metallic cover application.

- · Side discs application.

- · Weighing.

- · Labelling.

In the case of stacks of cut sheets, usual operations are:

- · Net weighing of the stack.

- · Plastic cover application.

- · Pallet loading.

- · Cover loading.

- · Cross banding of the stack.

- · Longitudinal banding of the stack.

- · Gross weighing of the stack.

- · Stack labelling.

- · Stacks piling.