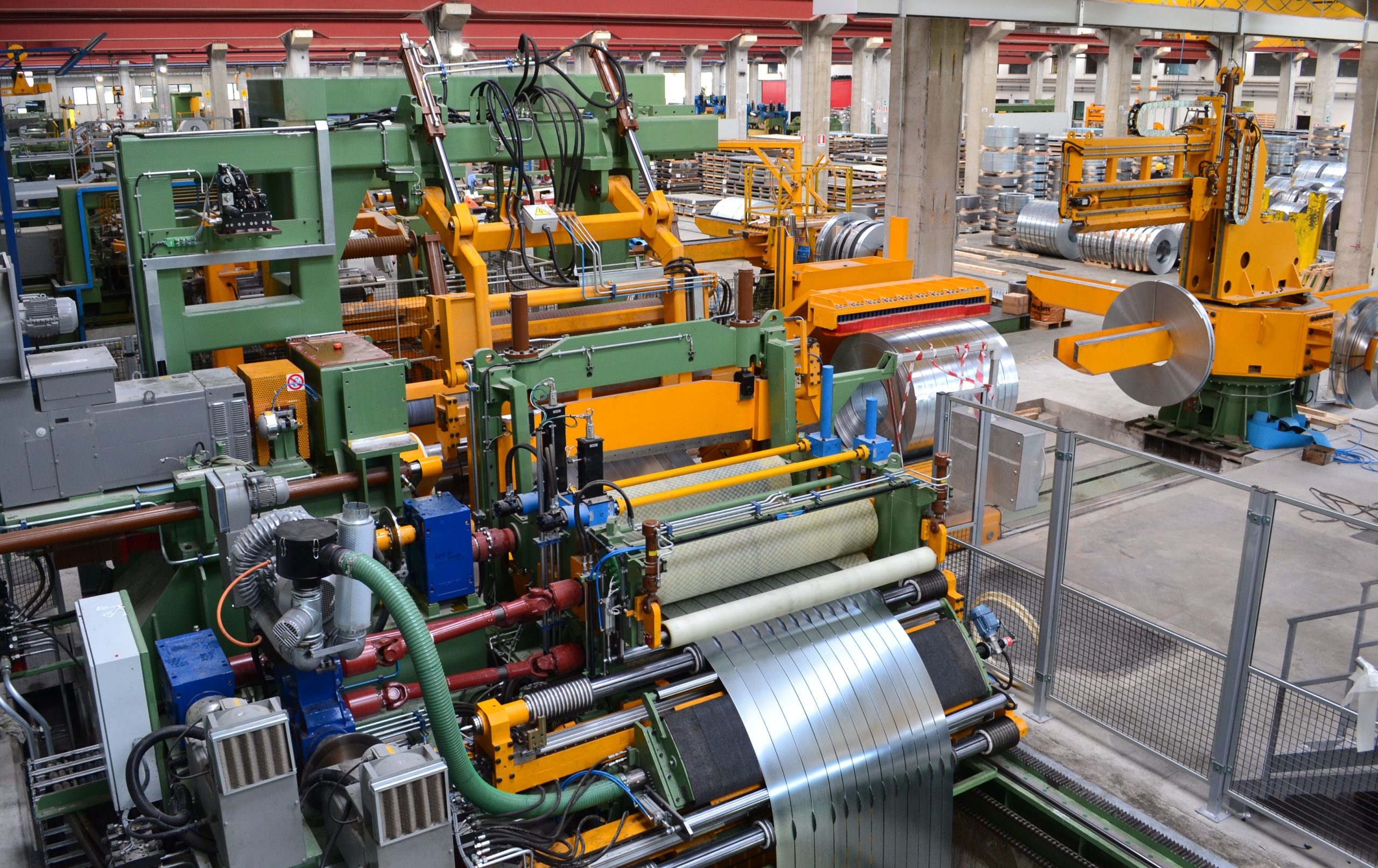

FRANCHINI LAMIERE, a company long-established as one of the most important Coil service center in Italy specialized in processing heavy gauge plate of high-grade steel, trust Salico technology by ordering our company a new Slitting Line to process steel coil 2.200 mm wide, capable to perform multiple slitting in the thickness range 1,5 to 8,0 mm and edge trimming up to 12,0 mm.

The new Slitting Line for FRANCHINI LAMIERE is beneficial of the over 40 years of experience of Salico in this field along with the latest design and features that Salico keeps always updated.

As a basic concept, the Line is designed to guarantee an uninterrupted production throughput with minimal intervention of Line operators who keep control of the functions of the Line comfortably from the Control Desks conveniently laid out.

Herein is a recap of the Slitting Line characteristics worth mentioning:

- The Coil Rotating Storage at the Entry of the Line both guarantees an efficient selection of the coil to feed into the Line and retrieve of coils not complete processed from the Line.

- The design “by steps” of the Opposite Mandrels of the Uncoiler fit three different coil inner diameters like 508, 610 and 760 mm.

- Coil Loading on Uncoiler is via Automatic Coil Centering along X and Y axis.

- During the uncoiling the Anti Coil Break Roll is kept in contact with the strip in avoidance the arise of cracks in the strip while the coil is being unwound.

- A Straightening Machine at entry section of the Line provides for strip is fed adequately flat into the Line during beginning of uncoiling of the coil then spins idle when the Line is in slitting run mode.

- The Slitting Shear features Slitting Tooling Auto Locking along with Auto Slitting Tooling Changeover carried out in a bunch of minutes, all this of Salico design and construction.

- Robotic Slitting Tooling Setup complementary to Slitting Shear makes this area is Complete Automatic for extreme ease and efficient operation.

- The Scrap Chopper is the indispensable machine to enable the easy management of the scrap edges trimmed from the strip; ease and safety in maintaining, efficiency and reliability, these are major points paid attention by Salico in designing this machine.

“Green technology has never been greener like with Salico Tensioning Bridle” abiding this motto Salico Tensioning Bridle is designed to perform tight and uniform winding of slit coils with one hundred percent recovering of the energy spent in recoiling and no use of felt to generate the necessary tension in the slit stripes for the proper recoiling of slit coils.

Downstream to recoiling of slit coils, an “L” shape offloading Coil Car with so called Hold-down Arm provided with “Piano Fingers” secure transfer the slit coils to an Exit Coil Turnstile implemented by an Automatic Circumferential Strapping Machine.

Salico is thankful to FRANCHINI LAMIERE for having pose its trust in its brand and guarantee full endeavour for achieving the wanted goals in this important project.